Introduction

Standard Platinum Resistance Thermometers (SPRTs) are highly precise thermometers that use the electrical resistance of platinum to measure temperatures with very high accuracy and repeatability. The International Temperature Scale of 1990 (ITS-90) uses SPRTs as an interpolation instrument to establish a globally uniform and reliable basis for temperature measurements and calibrations.

Table of Contents

What are SPRTs and Why are They Important?

In the field of precision measurement, Standard Platinum Resistance Thermometers (SPRTs) are essential for highly accurate temperature measurements. These specialized thermometers take advantage of the characteristic that the electrical resistance of pure platinum changes predictably with temperature, delivering measurements with very high accuracy and consistency.

This accuracy makes SPRTs a crucial tool in laboratories and industries worldwide, where they serve as primary reference devices. They are the gold standard in temperature measurement, relied upon by international standards and calibrations to ensure the comparability of temperature measurements across borders and disciplines. Their use is fundamental in maintaining the International Temperature Scale of 1990 (ITS-90), which acts as a global guideline for temperature measurement and significantly supports quality and accuracy in science, medicine, industry, and environmental monitoring.

SPRT and temperature scale?

The International Temperature Scale of 1990 (ITS-90) is the current temperature scale established worldwide as the basis for precise temperature measurements. The goal of ITS-90 is to provide a uniform, accurate, and globally recognized scale to ensure the comparability of temperature measurements. Unlike previous scales, ITS-90 is primarily based on the temperatures of defining fixed points determined by the physical properties of pure substances. This includes the triple points—the states at which a substance simultaneously exists in solid, liquid, and gaseous phases, such as the triple point of water—as well as the freezing points of various metals, such as tin, zinc, or aluminum. These fixed points offer extremely precise and reproducible reference temperatures.

Standard Platinum Resistance Thermometers (SPRTs) are used to be calibrated at these defining temperature fixed points. The accuracy of the temperature fixed points and the SPRTs is crucial for the implementation of ITS-90. By utilizing these set temperature fixed points, ITS-90 enables the highest accuracy and reproducibility in temperature measurement to date, making it indispensable for applications in research, industry, and quality control.

Further information about ITS-90 can be found here: The International Temperature Scale of 1990 (ITS-90)

How Resistance Thermometers Work

Standard Platinum Resistance Thermometers (SPRTs) use the precisely defined relationship between temperature and the electrical resistance of pure platinum to measure temperatures. By measuring the change in this resistance, they can determine temperatures with the highest current accuracy and repeatability.

Advertisement

Reference thermometer for extremely low temperatures

Ideal for precise measurements at ultra-low temperatures from -200 °C to 250 °C. The quartz-free design ensures stability even in extreme conditions, preventing breakage during freezing. Its compact temperature detector minimizes heat dissipation, delivering highly accurate results. Available with accredited calibration according to DIN EN ISO/IEC 17025 (DAkkS).

The Physical Basis

Standard Platinum Resistance Thermometers (SPRTs) are based on the principle that the electrical resistance of a metallic conductor, in this case platinum, changes with temperature. This temperature dependence of resistance is particularly well characterized and reproducible for pure platinum, making it the ideal material for precise temperature measurements. The operation of an SPRT is based on the principle of electrical resistance, more specifically on the physical property known as the temperature coefficient of resistance. For platinum, this coefficient is positive, meaning that resistance increases with rising temperature.

An SPRT consists of a fine platinum wire wound on a non-conductive support, such as quartz. The design must ensure that the platinum wire can expand completely free of stress. This wire is embedded in a protective atmosphere to shield it from environmental influences while also ensuring that it can be directly exposed to the temperature being measured.

When a temperature change occurs, the electrical resistance of the platinum wire changes in a predictable manner. This change is measured using a precision temperature bridge that provides very accurate resistance values. From the measured resistance, the temperature can be determined using known relationships.

The accuracy of an SPRT is based on the purity of the platinum used, the construction of the thermometer, and the precision of the measuring instruments used to determine the resistance. International standards for SPRTs are set by organizations such as the International Bureau of Weights and Measures (BIPM), the Physikalisch-Technische Bundesanstalt (PTB) in Braunschweig and Berlin, or other National Metrology Institutes (NMIs). NMIs around the world, like the PTB in Germany, are central organizations for establishing and preserving national measurement standards and play a key role in the global harmonization of measurement procedures.

Defining strict requirements for the construction and calibration of these thermometers ensures that they enable comparable temperature measurements worldwide. These standards allow SPRTs to serve as primary reference thermometers, which are calibrated at the defining fixed points of the International Temperature Scale of 1990 (ITS-90).

The Role of Platinum and Why It Was Chosen as the Material

Platinum plays a crucial role in the operation of Standard Platinum Resistance Thermometers (SPRTs) due to several unique properties that make it the ideal material for precise temperature measurements. The choice of platinum for SPRTs is based on the following main reasons:

High chemical stability: Platinum is an extremely inert metal, meaning it does not react or only reacts very minimally with other substances. This chemical stability ensures that the material remains unchanged even with long-term use under various environmental conditions, improving the reliability and long-term stability of measurements.

Uniform temperature dependence: The electrical resistance of platinum changes in a predictable and uniform manner with temperature. This property allows for precise and reproducible temperature measurements. The linear relationship between temperature and resistance in platinum facilitates calibration and makes the measurement results comparable worldwide.

High temperature resistance: Platinum can withstand high temperatures without changing its physical or chemical properties. This high temperature resistance expands the usable temperature range of SPRTs, making them suitable for a wide range of applications, from very low to very high temperatures.

Good electrical conductivity: As a metal, platinum has good electrical conductivity, which is necessary for the precise measurement of changes in resistance. This conductivity contributes to the accuracy and sensitivity of the temperature measurement.

Long-term stability: In addition to its chemical stability, platinum also exhibits excellent long-term stability in terms of its physical properties, including electrical resistance. This stability is essential for maintaining calibration and for repeated measurements over long periods.

The Importance of SPRTs in ITS-90

SPRTs are used as primary interpolation instruments within the International Temperature Scale of 1990 (ITS-90), enabling accurate measurement between the defining fixed points.

The Basis: Kelvin and Celsius

A key component of the International Temperature Scale of 1990 (ITS-90) is the definition of a series of mathematical and thermodynamic relationships that are essential for the use of Standard Platinum Resistance Thermometers (SPRTs). At the top is the Kelvin (K), the base unit of thermodynamic temperature (T), which forms the Base for precise temperature measurements.

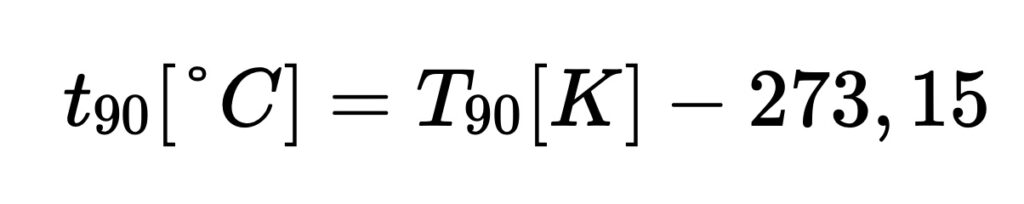

In practical applications, temperatures are often given as Celsius temperatures t90, with the conversion as follows:

This allows for the efficient use of both Kelvin and degrees Celsius (°C) depending on the context. Particularly for temperatures below the freezing point, Kelvin is preferred, while above it, degrees Celsius is used.

W-Values of SPRTs

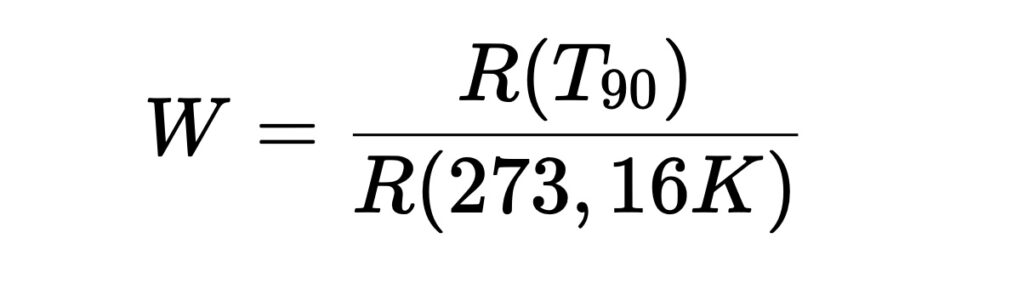

A key concept within the International Temperature Scale of 1990 (ITS-90) is the use of resistance ratios, commonly known as W-values. These W-values form the basis for precise temperature measurement and calibration with Standard Platinum Resistance Thermometers (SPRTs). The basic equation for the W-value is defined as follows:

In this context, R(T90) represents the ohmic resistance at the temperature T90, and R(273.16K) stands for the ohmic resistance at the triple point of water, precisely at 0.01°C.

The Definition and Selection Criteria for SPRTs

Within the International Temperature Scale of 1990 (ITS-90), the W-values are used in the definition and selection of Standard Platinum Resistance Thermometers (SPRTs). These criteria ensure that only the most precise thermometers are used for accurate temperature measurements according to ITS-90 standards.

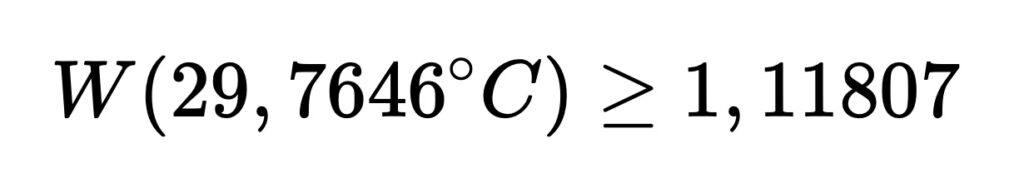

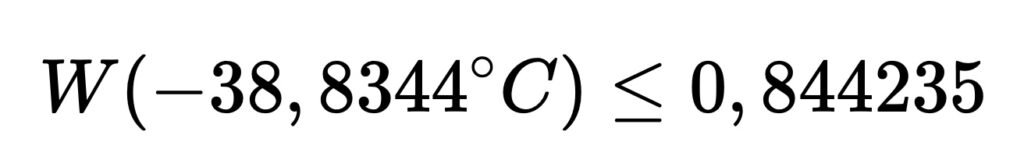

An SPRT must meet specific resistance ratios, or W-values, to be classified as such. The criteria are as follows:

At a temperature of 29.7646°C, the W-value must be at least 1.11807.

Alternatively, or additionally, at a temperature of -38.8344°C, the W-value must not exceed 0.844235.

If a Platinum Resistance Thermometer is used up to the freezing point of silver, the following applies as well:

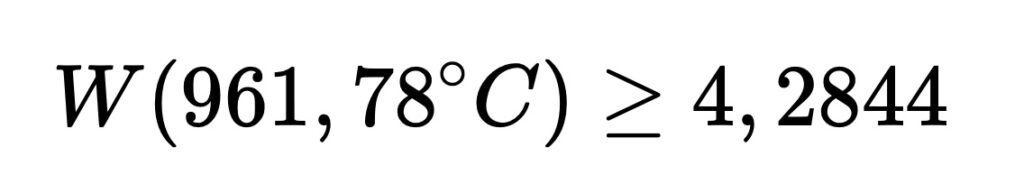

For thermometers that are used up to the freezing point of silver (961.78°C), an additional criterion is that the W-value must be at least 4.2844. These specific requirements ensure that SPRTs have sufficient linearity across the entire temperature range.

SPRT Reference and Inverse Functions

The International Temperature Scale of 1990 (ITS-90) utilizes specific reference and inverse functions to ensure temperature measurements with Standard Platinum Resistance Thermometers (SPRTs). These functions are defined for two main temperature ranges:

Temperature range from 13.8033 K to 273.16 K

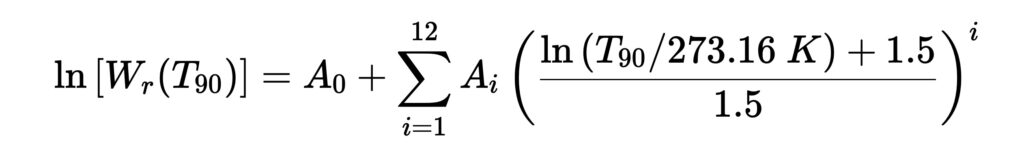

For this temperature range, ITS-90 defines a reference function that describes the mathematically ideal ratio between the W-value and the temperature T90.

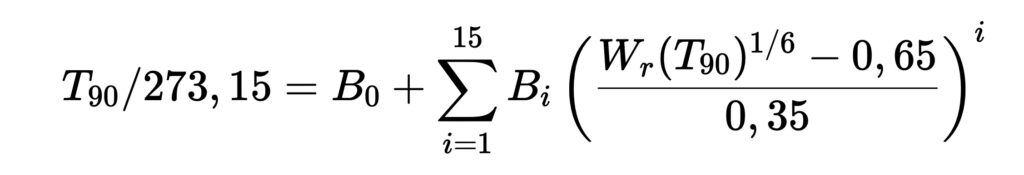

To determine the corresponding temperature from a measured W-value, an inverse function is used, which allows a maximum deviation of only 0.1 mK from the reference function.

The coefficients A0, B0, Ai, and Bi, necessary for the application of these functions, are found in ITS-90.

Temperature Range from 0°C to 961.78°C:

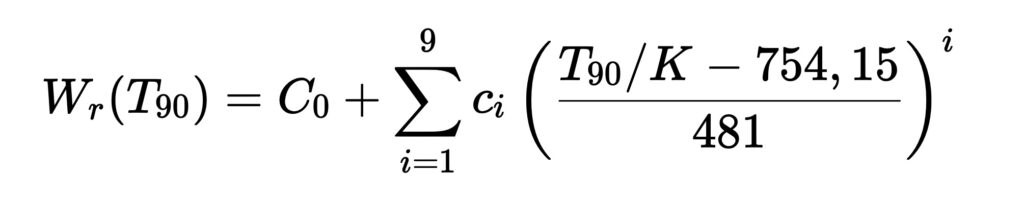

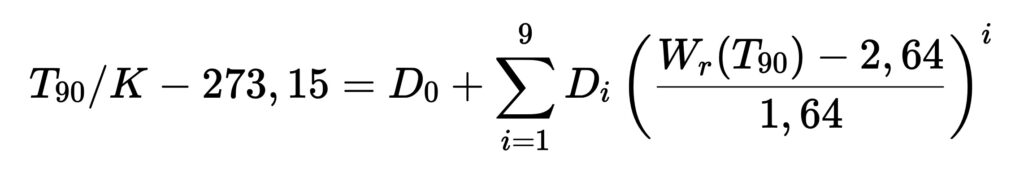

In this wide temperature range, specific reference and inverse functions are also provided

The reference function again defines the ideal ratio for precise temperature measurements, while the inverse function allows for the accurate determination of the temperature T90 based on a given W-value, with a small maximum deviation of 0.13 mK.

The implementation of these functions requires the coefficients C0, D0, Ci, and Di, which are also specified in ITS-90.

SPRT Deviation Functions

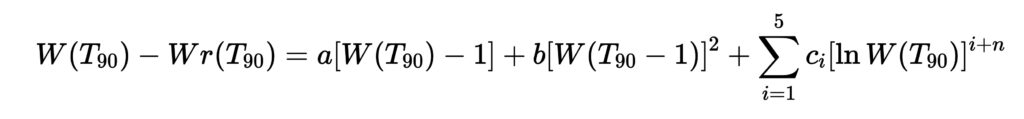

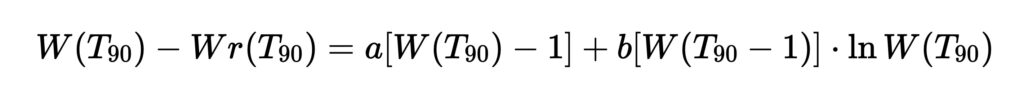

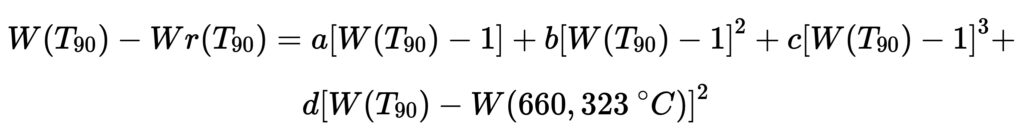

Deviation functions are a crucial tool of the International Temperature Scale of 1990 (ITS-90). These functions enable the accurate calculation of corresponding temperatures from the measured resistance values of Standard Platinum Resistance Thermometers (SPRTs). Similar to the reference functions, the deviation functions are divided into three main temperature ranges:

Temperature Range from 13.8033 K to 273.16 K

Temperature Range from 83.8058 K to 273.16 K

Temperature Range from -38.8344°C to 961.78°C

Deviation functions reflect the actual ratio between the measured resistance values and the temperatures according to ITS-90, allowing for direct and accurate temperature calculation.

A key element of these functions are the individual coefficients a, b, c, and d, which must be calculated specifically for each thermometer. These coefficients ensure that the deviation function takes into account the individual characteristics of each thermometer, necessitating individual calibration.

This customized adaptation is critical for the accuracy of temperature measurements and highlights the necessity of precise and individual calibration of each SPRT according to ITS-90.

Advantages and Limitations of SPRTs

SPRTs offer extraordinary precision and reproducibility in temperature measurements, supported by their fundamental role in ITS-90. Limitations include high costs, a certain susceptibility to mechanical and chemical influences, and limited applicability in extreme temperature ranges or harsh environments.

Advantages of SPRTs Over Other Thermometer Types

Standard Platinum Resistance Thermometers (SPRTs) offer exceptional accuracy and reproducibility in temperature measurement that sets apart them from other thermometer types. Their precision is due to the stable and predictable change in the electrical resistance of platinum with temperature, making them preferred instruments for primary reference measurements and the calibration of other thermometers. Additionally, platinum’s high chemical stability and low susceptibility to aging processes ensure long-term consistency of measurements, which is essential for applications where high accuracy is required over extended periods.

Compared to other thermometer types, such as thermistors, thermocouples, or liquid-in-glass thermometers, SPRTs provide significantly higher accuracy and stability. These properties make them the first choice for scientific research and metrology applications where precision is paramount. While other thermometer types may be preferred for specific applications due to their simplicity, robustness, or specific temperature ranges, the unparalleled precision and reliability of SPRTs for fundamental temperature standards and high-precision measurement tasks remain unmatched.

Limitations or Challenges in Using SPRTs

Despite their outstanding accuracy and reproducibility, Standard Platinum Resistance Thermometers (SPRTs) also have limitations and challenges that need to be considered in their usage. One of the main limitations of SPRTs is their relatively high initial cost and calibration expenses, making them less practical for everyday or industrial applications where large quantities or cost-effective solutions are required. Additionally, SPRTs are sensitive to mechanical stresses and contaminants, meaning they must be handled and stored carefully to maintain their accuracy and longevity.

Another challenge is the temperature range in which SPRTs can be used. Although suitable for a wide temperature range, they are not optimal for extremely high temperatures or very harsh conditions, where alternative types of thermometers such as thermocouples may be better suited. Furthermore, utilizing the full accuracy of SPRTs requires specialized measurement equipment and expertise to conduct precise measurements and interpret the data correctly. These requirements typically restrict their use to laboratory environments or specialized industrial applications where the necessary resources and expertise are available.

Applications of SPRTs and ITS-90 in Practice

Standard Platinum Resistance Thermometers (SPRTs) and the International Temperature Scale of 1990 (ITS-90) find practical applications in a variety of fields where precision and reliability in temperature measurements are required. A central application of SPRTs lies in the calibration of other thermometers and in metrology, where they serve as primary reference thermometers. In national metrology institutes, SPRTs are used to realize temperature standards necessary for the traceability of temperature measurements in industry, research, and quality assurance.

Furthermore, SPRTs play an important role in research and development, particularly in physics and materials science, where precise temperature control and measurement are crucial for understanding thermal properties and phenomena. In the pharmaceutical industry and biotechnology, SPRTs and the ITS-90 are used for precise temperature control in the production and storage of temperature-sensitive products such as vaccines and medications. They are also crucial in environmental monitoring and research, where accurate temperature data are needed for climate models and ecological studies.

The precise adherence to ITS-90 enables globally comparable temperature measurements, which are essential for international trade relations, quality standards, and safety regulations. Whether in food quality assurance, monitoring industrial processes, or calibrating medical devices, the precision and reliability of SPRTs and compliance with ITS-90 ensure confidence and safety in many aspects of daily life and science.

How to Properly Cool Standard Platinum Resistance Thermometers (SPRTs)?

An often-discussed topic is the question: How should precision thermometers, such as Standard Platinum Resistance Thermometers (SPRTs), be cooled correctly? Opinions vary widely on whether they should be cooled quickly, slowly, or using temperature ramps.

In addition to the thermal and mechanical effects that can occur during heating and cooling, the three-dimensional oxidation of platinum plays a significant role. Interestingly, there is no universally accepted answer to this question. However, two excellent publications can provide valuable guidance:

NIST Special Publication 250-81: “Standard Platinum Resistance Thermometer Calibrations from the Ar TP to the Ag FP” by G. F. Strouse

This publication by the National Institute of Standards and Technology (NIST) describes a detailed procedure for cooling SPRTs used at temperatures up to 675 °C. The process is as follows:

- The SPRT is heated from 475 °C to 675 °C over a period of 30 minutes.

- It is then held at 675 °C for 2.5 hours.

- Cooling is done slowly by reducing the temperature from 675 °C to 475 °C over three hours.

- Finally, the HTSPRT is removed from the oven at 475 °C.

CCT Guide: “Guide to the Realization of the ITS-90: Platinum Resistance Thermometry”

This publication, referring to the International Temperature Scale (ITS-90), outlines the procedure for cooling SPRTs used up to 660 °C. The process is as follows:

- First, the SPRT is annealed in an annealing furnace at 480 °C to 500 °C.

- The temperature is then slowly increased to about 675 °C over 45 to 60 minutes.

- The SPRT is annealed at this temperature for four hours to reduce thermal stress.

- Cooling is done slowly to about 480 °C over four hours, before the SPRT is brought directly to room temperature.

Both approaches are helpful and provide guidance, but they are not identical. A standardized procedure would certainly be desirable. Both methods aim to minimize stresses in the platinum of the SPRT, but they differ in their specifics. Which approach is the most suitable often depends on specific requirements and applications.

Future of Temperature Measurements and the Role of SPRTs

The future of temperature measurements foresees continuous advancements towards even greater precision, reliability, and expanded applications, with Standard Platinum Resistance Thermometers (SPRTs) likely to continue playing a central role. As the quest for improved materials, more advanced measurement techniques, and the integration of digital technologies progresses, it is expected that the accuracy and applicability of temperature measurements will further increase. SPRTs, already forming the foundation for highly precise temperature measurement, could be further enhanced in their performance and versatility through these innovations.

At the same time, the significance of the International Temperature Scale of 1990 (ITS-90) is likely to be complemented or expanded by the development of new and revised temperature scales that offer even more precise and universally applicable measurement standards. Research in the field of quantum physics and new discoveries in materials science could lead to entirely new approaches in temperature measurement, yielding SPRTs in new configurations or even entirely new types of reference thermometers.

Despite these future developments, the role of SPRTs as highly precise standard instruments for temperature measurement is likely to remain, especially in areas where the highest measurement accuracy and reliability are required. Their ability to serve as fundamental references for the calibration and verification of other thermometers will continue to be crucial in ensuring the comparability of temperature measurements worldwide.

Advertisement

Calibration of standard platinum resistance thermometers (SPRTs)

Klasmeier offers accredited calibrations according to DIN EN ISO/IEC 17025 (DAkkS) for SPRTs. These calibrations are performed at ITS-90 temperature fixed points, ensuring high accuracy and reliability. Both slim and primary temperature fixed points are used, and thermometers with an immersion depth of at least 300 mm can be calibrated.

Conclusion

To sum up, Standard Platinum Resistance Thermometers (SPRTs) and the International Temperature Scale of 1990 (ITS-90) are crucial tools for measuring temperature accurately. SPRTs have special features like high stability and precise temperature-resistance relationships, making them very accurate and reliable. They are essential for calibration purposes and are used widely in science and industry. The ITS-90 defines these precision instruments to ensure consistent and comparable temperature measurements worldwide, which is important for research, quality control, and industrial processes.

The role of SPRTs and the ITS-90 in ensuring measurement accuracy is vital as they contribute directly to safety, efficiency, and innovation in many areas of daily life and the global economy. The future of temperature measurement promises even more precise and versatile methods driven by technological advancements and scientific research. SPRTs and their potential advancements are expected to continue playing a central role by setting standards for precision and reliability.

The importance of accurate temperature measurements and the role of SPRTs and the ITS-90 extend beyond the laboratory. They are crucial for advancing scientific knowledge, improving industrial processes, and ensuring product quality, ultimately contributing to improved quality of life and environmental safety. Continuously developing and adapting these measurement standards and technologies will remain an important task to meet the growing demands of a rapidly evolving world.

Source

- Walter Blanke: Die Internationale Temperaturskala von 1990: ITS-90

- Frank Bernhard: Handbuch der Technischen Temperaturmessung, 2. Auflage

- Thomas Klasmeier: Tabellenbuch „Temperatur“, Ausgabe 3

- Strouse, G. F. Standard Platinum Resistance Thermometer Calibrations from the Ar TP to the Ag FP. NIST Special Publication 250-81, National Institute of Standards and Technology, 2008.

- Consultative Committee for Thermometry. Guide to the Realization of the ITS-90: Platinum Resistance Thermometry. Bureau International des Poids et Mesures, 2008.