Controlled tempering increases the stability of thermometers.

In temperature measurement, stabilization helps to improve the accuracy and lifespan of thermometers.

In the DAkkS calibration laboratory (accredited according to DIN EN ISO/IEC 17025) of Klasmeier, various temperature sensors such as standard thermometers, reference thermometers, SPRTs, HTPRTs, Pt100 and Pt25 are used. These sensors undergo a defined temperature cycle to be fully tempered.

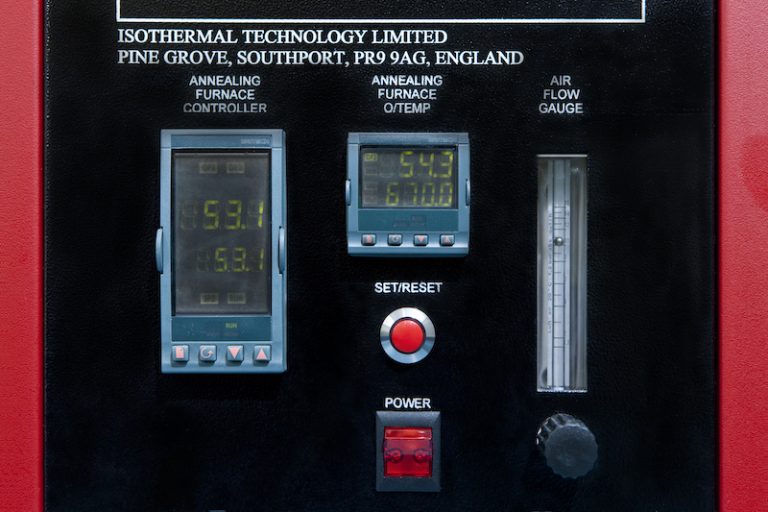

This is done in a special ISOTECH stabilization oven.

Table of Contents

Why is stabilizing thermometers necessary?

The use of platinum resistance thermometers in laboratory applications reveals a certain instability in the measuring resistances over time, a phenomenon known as “thermometer drift”. The reasons for this drift are varied and can include mechanical effects such as vibrations during transport, mechanical shocks, or the use of circulation baths. Contamination, diffusion of foreign substances, and the use of silicone oil as a calibration medium can also contribute. Other factors are thermal stresses due to long-term use at varying and high temperatures and improper cooling procedures. Oxidation effects on the measuring resistance during prolonged use between 200 °C and 450 °C can also lead to drift effects.

How does stabilization work?

A proven approach to combat this drift is the controlled thermal treatment of thermometers, also known as aging or annealing. This process can, in many cases, reverse the unwanted changes and improve the stability of the thermometer.

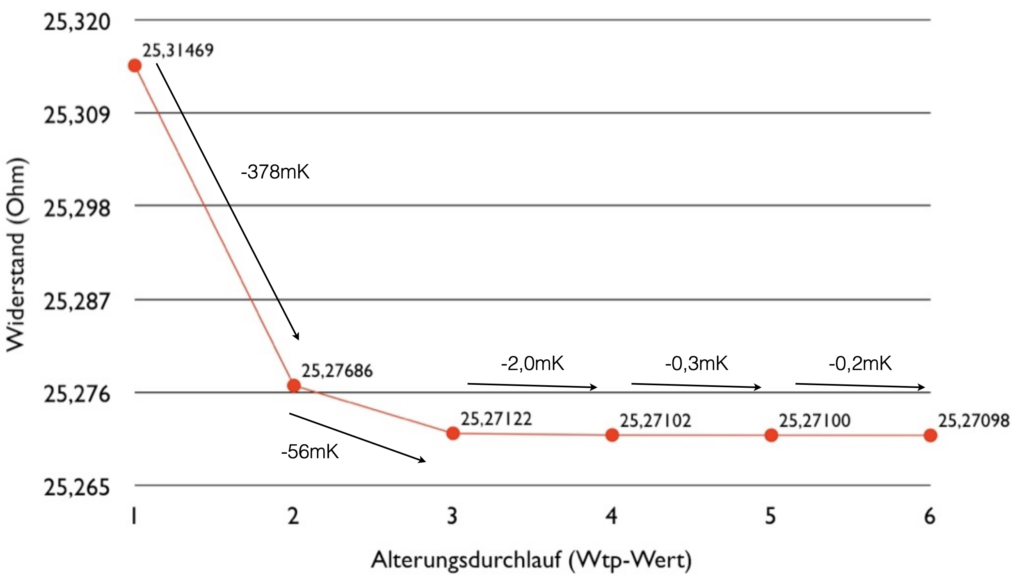

A look at the typical aging process at the water triple point of a PT25 standard thermometer (SPRT) illustrates the efficiency of this method. After each aging cycle, the stability of the thermometer should be checked and documented to ensure a smooth process.

How is the stabilization of thermometers carried out?

A central challenge in calibration is to ensure that the calibrated thermometers always remain within their specifications. This is achieved through stabilization.

The stabilization furnace developed specifically for this task by ISOTECH heats the thermometers to the calibration temperature, allows them to age there, and then cools them down. The furnace can cover temperatures from room temperature up to 1000°C, allowing all types of SPRTs to age up to the silver fixed point (961.78 °C).

In eigener Sache

Furnace for stabilizing thermometers

The stabilization furnace, developed by ISOTECH, is used for the preparation of standard thermometers (SPRTs) and similar types of thermometers such as Pt100 and Pt25, reference thermometers, etc.

It is used for preheating, annealing, and cooling thermometers before their calibration. With a temperature range from room temperature to 1000°C, the furnace is capable of stabilizing a variety of thermometer designs, including SPRTs.

It is also important to note that the significance of aging increases with the calibration temperature. The higher the operating temperature of the temperature sensors, the more porous the quartz becomes, which can lead to rapid contamination of the SPRT. To prevent these contaminations at high temperatures, the temperature sensors are continuously purged with preheated air.

How are aging parameters and air purging set?

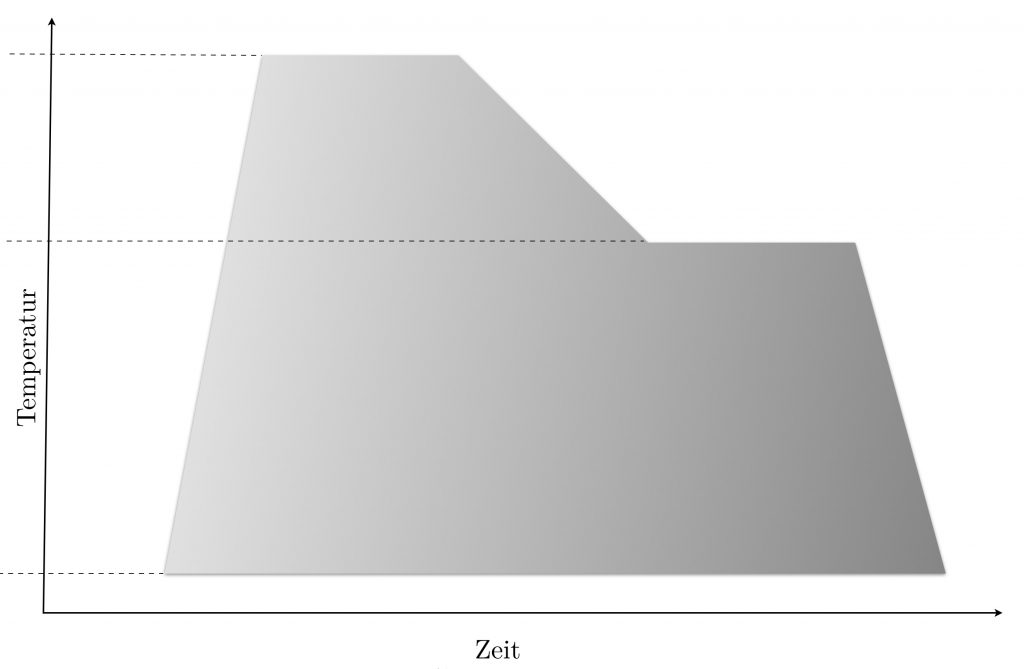

The careful adjustment of aging parameters is just as important as selecting the right stabilization furnace. The stabilization furnace is programmed using eXacal software to ensure that heating and cooling to the various aging temperatures occur at a defined rate. This prevents the measuring resistors from being excessively stressed or damaged by large temperature jumps. When cooling from high temperatures, a tempering phase is maintained to protect the measuring resistor.

The aging cycles are repeated until the temperature sensor to be calibrated has become stable within its specification. The progress of aging is measured, evaluated, and documented at the water triple point.

In summary, controlled aging and tempering of thermometers is an essential method for ensuring high measurement precision and a long service life of the instruments. It allows specialists in calibration services like Klasmeier to consistently deliver high-quality and accurate measurement results.

Sources:

- Frank Bernhard: Handbuch der Technischen Temperaturmessung, 2. Auflage

- Thomas Klasmeier: Table Book “Temperature”, Edition 3