Thermocouples are thermometers that are widely used in industrial temperature measurement. They are particularly useful for measuring high temperatures. But how do thermocouples work? How can you measure temperatures with two simple wires? The key to understanding is in the Seebeck effect.

Table of Contents

Background on thermocouples

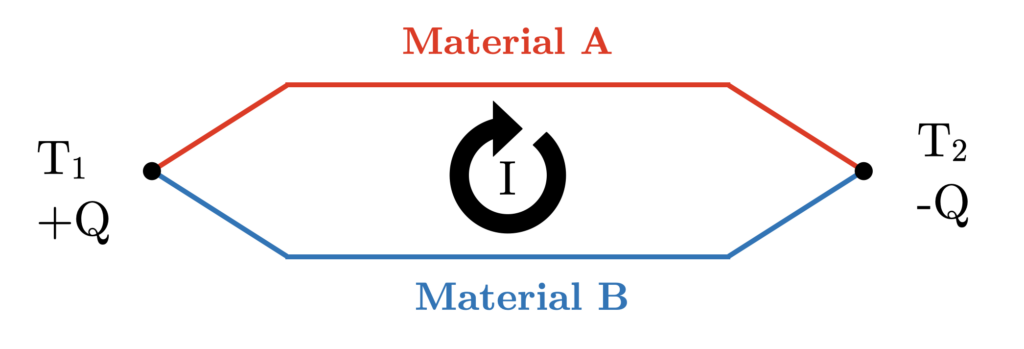

The Seebeck effect, first described by Thomas Johann Seebeck in 1821, is the phenomenon that a weak electric current flows in a circuit consisting of two different conductors when the contact points of the conductors have different temperatures. This connection of conductors is called a thermocouple.

Explanation of the Seebeck effect

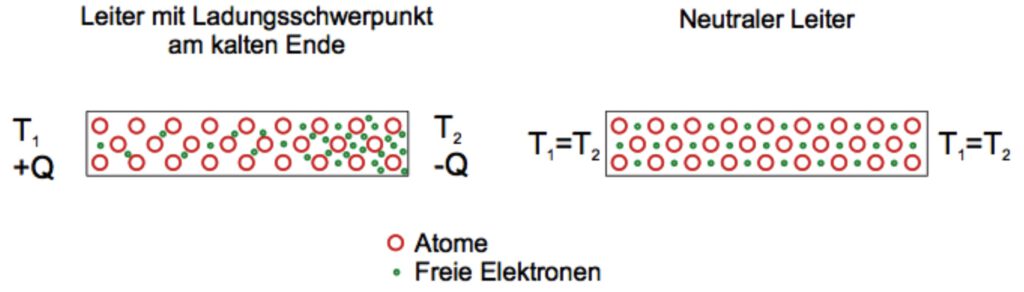

To understand the Seebeck effect, we can look at a single electrical conductor. Inside the conductor are atoms between which free electrons move. In a state of thermal balance, the free electrons are equally spaced in the conductor.

However, when heat is added to one side of the conductor, the velocity of the free electrons increases at that point. The increased speed of the electrons displaces them to the cooler end of the conductor. A centre of charge is created at this cold spot.

However, this effect alone does not allow reproducible temperature measurement, as it is highly temperature dependent and does not provide a constant relationship between temperature and voltage.

Use of the Seebeck effect

To achieve a reproducible temperature measurement, two different metals with different electron properties in relation to temperature can be used. When these metals are connected and there is a temperature difference between the junctions, different charges centres of gravity and a measurable thermoelectric voltage are created.

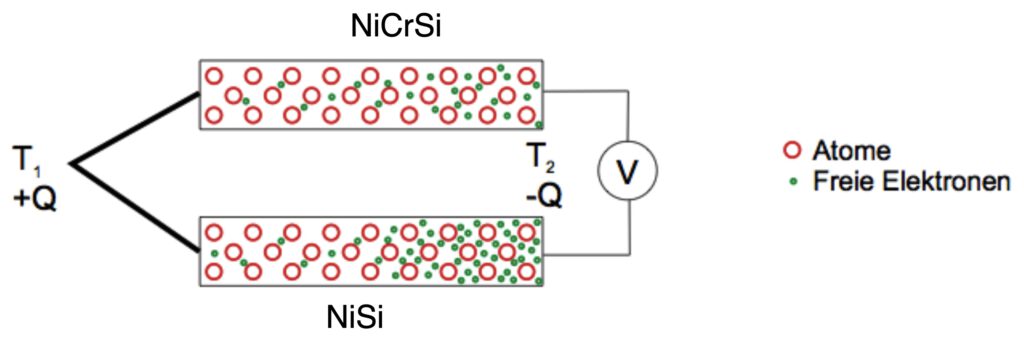

An example of a thermocouple is the type N thermocouple, consisting of NiCrSi and NiSi. If there is a temperature difference between the contact points of the two conductors, a measurable thermoelectric voltage is produced, which can be measured with a voltmeter.

Two conditions are important here:

- The two conductors must be connected to each other.

- There must be a temperature difference between the connection points T1 and T2.

Common thermocouple types

Thermocouples are available in different types, each characterised by the material combination of their wires. Each type has its own advantages and disadvantages as well as specific applications. Here are some of the most common thermocouple types:

- Type B (platinum-rhodium/platinum):

- Temperature range: 0°C to 1,800°C.

- High temperature accuracy

- Type E (nickel-chromium/constantan):

- Temperature range: -270°C to 1,000°C

- High thermoelectric voltage and good accuracy

- Type J (iron/constantan):

- Temperature range: -210°C to 1,200°C

- Not suitable for oxidising atmospheres above 550°C

- Type K (nickel-chromium/nickel-alumel):

- Temperature range: -200°C to 1,260°C

- Wide temperature range and cost-effective

- Type N (Nicrosil/Nisil):

- Temperature range: -270°C to 1,300°C

- Better thermal stability and oxidation resistance than type K

- Type R (Platinum-Rhodium/Platinum):

- Temperature range: -50°C to 1,760°C

- High temperature accuracy

- Type S (platinum-rhodium/platinum):

- Temperature range: -50°C to 1,760°C

- Similar to type R, often used in the glass and ceramics industry

- Type T (copper/constantan):

- Temperature range: -270°C to 400°C

- Good for low temperatures, stable in oxidising atmospheres

Labelling of thermocouples by plug colours

Thermocouples are nowadays essential components of many industrial applications and scientific research. Their ability to measure temperatures precisely and reliably makes them an important instrument. The correct identification of thermocouples is crucial for correct temperature measurement.

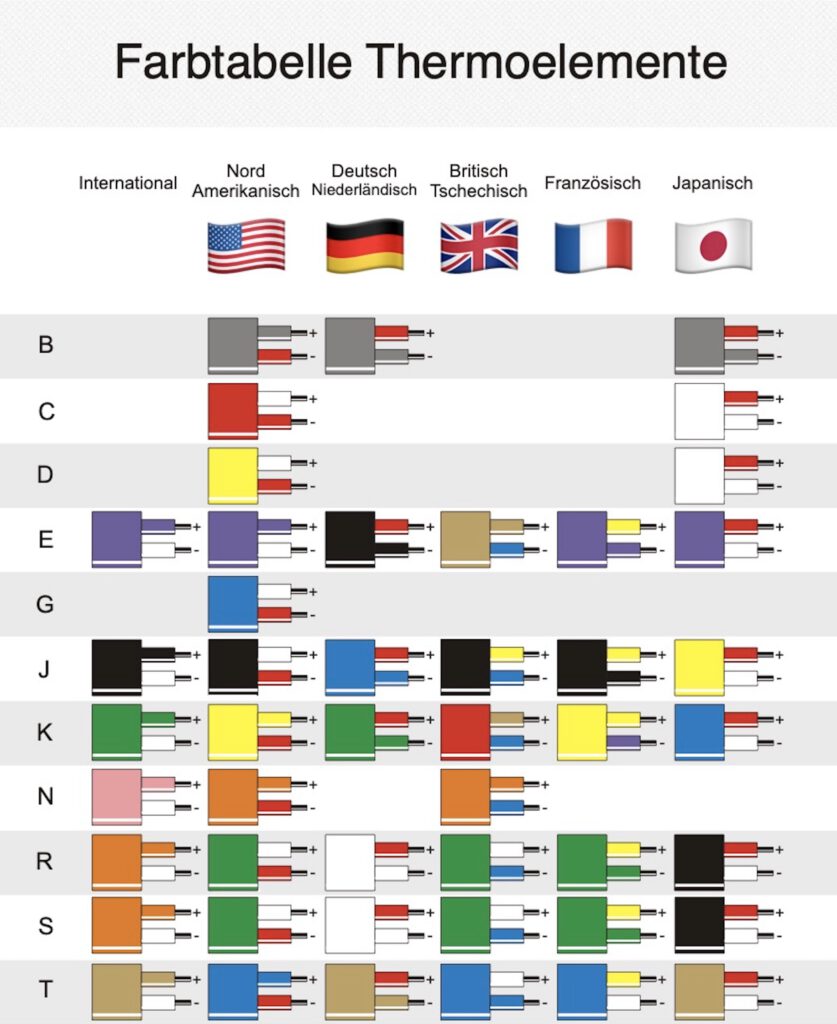

One way to identify thermocouples is to check the colour of the connector and insulation. Over the years, a variety of thermocouple types have been developed, consisting of different material pairings. In order to make a clear identification possible, the different types have been given identification colours. However, it should be noted that there are different colour codes for different countries, for example those classified according to “IEC” (International Electrotechnical Commission), “BS” (British Standard) or “ANSI” (American National Standards Institute).

An example of the differences in colour coding is the type R thermocouple. According to the IEC standard, this thermocouple has orange insulation, while according to the BS standard it is marked green. These differences can cause confusion, especially when thermocouples from different countries are used. It is therefore important to know and take into account the relevant standards.

Below are some common thermocouple types and their corresponding colour codes:

Type K: IEC – green; BS – yellow; ANSI – yellow

Type J: IEC – black; BS – white; ANSI – white

Type T: IEC – brown; BS – blue; ANSI – blue

Type E: IEC – purple; BS – purple; ANSI – purple

Type N: IEC – pink; BS – orange; ANSI – orange

Download colour table of thermocouples as PDF:

_

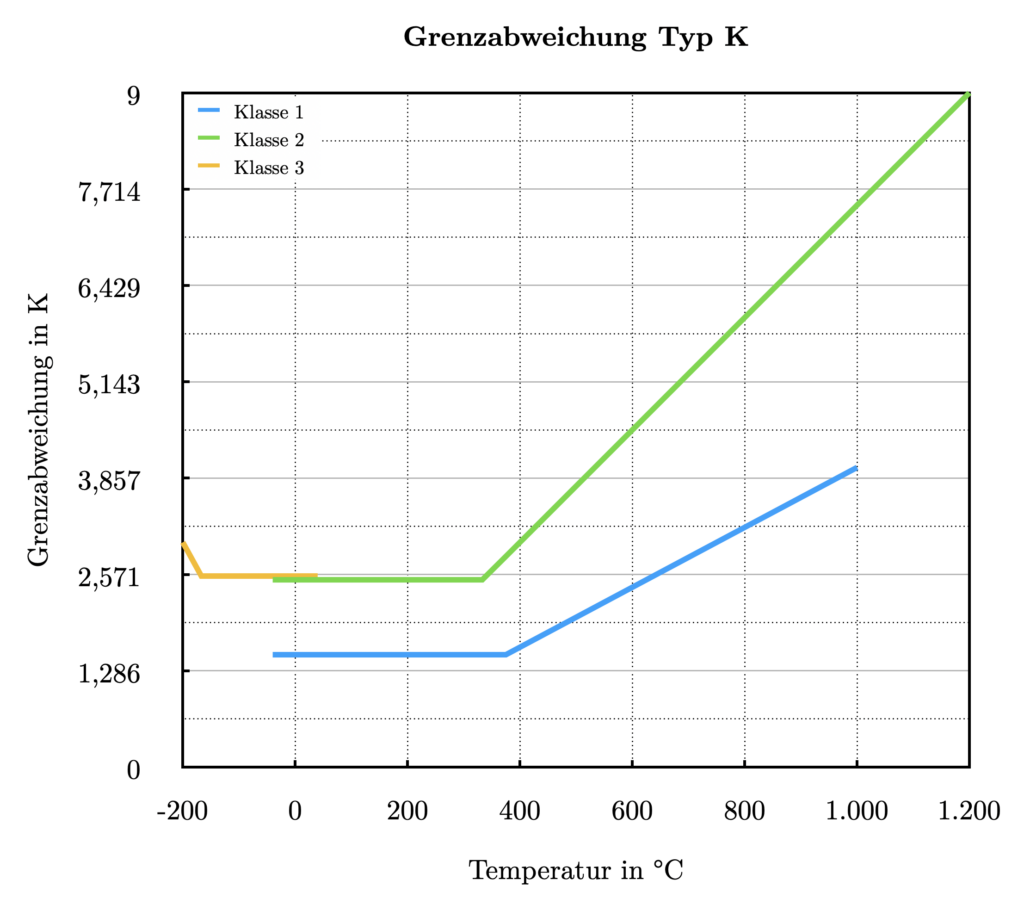

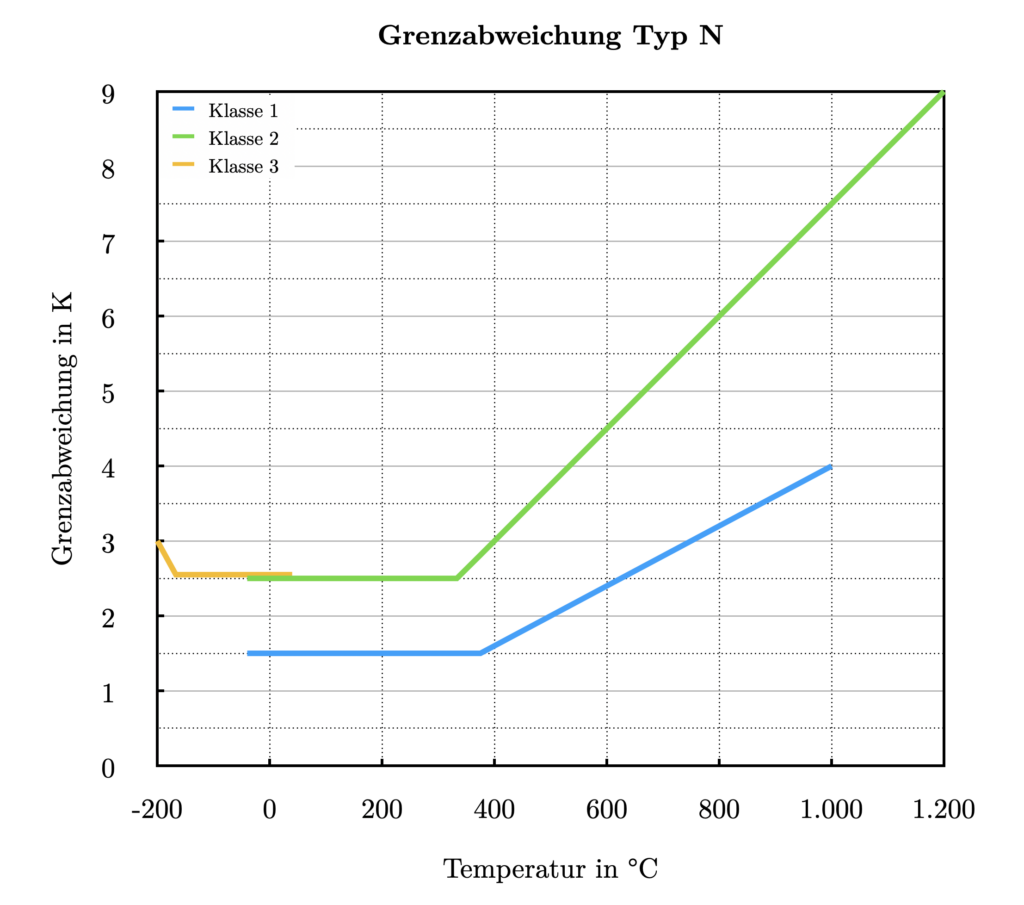

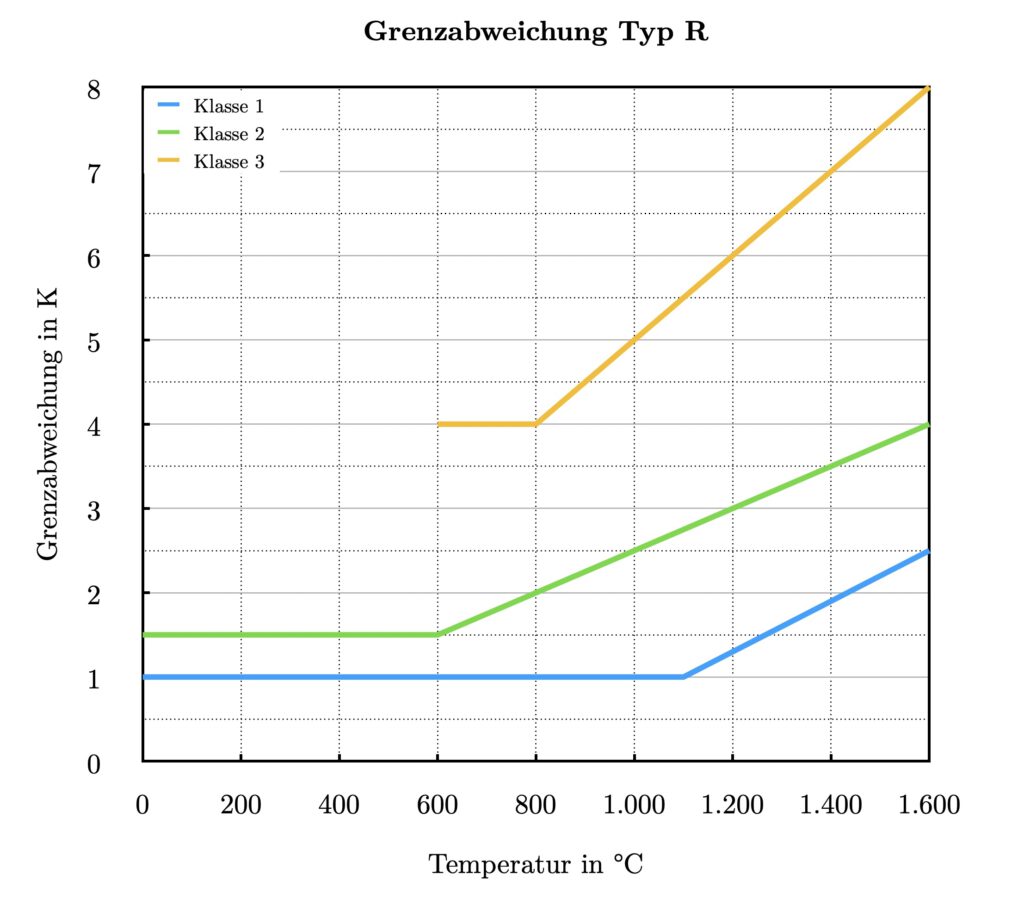

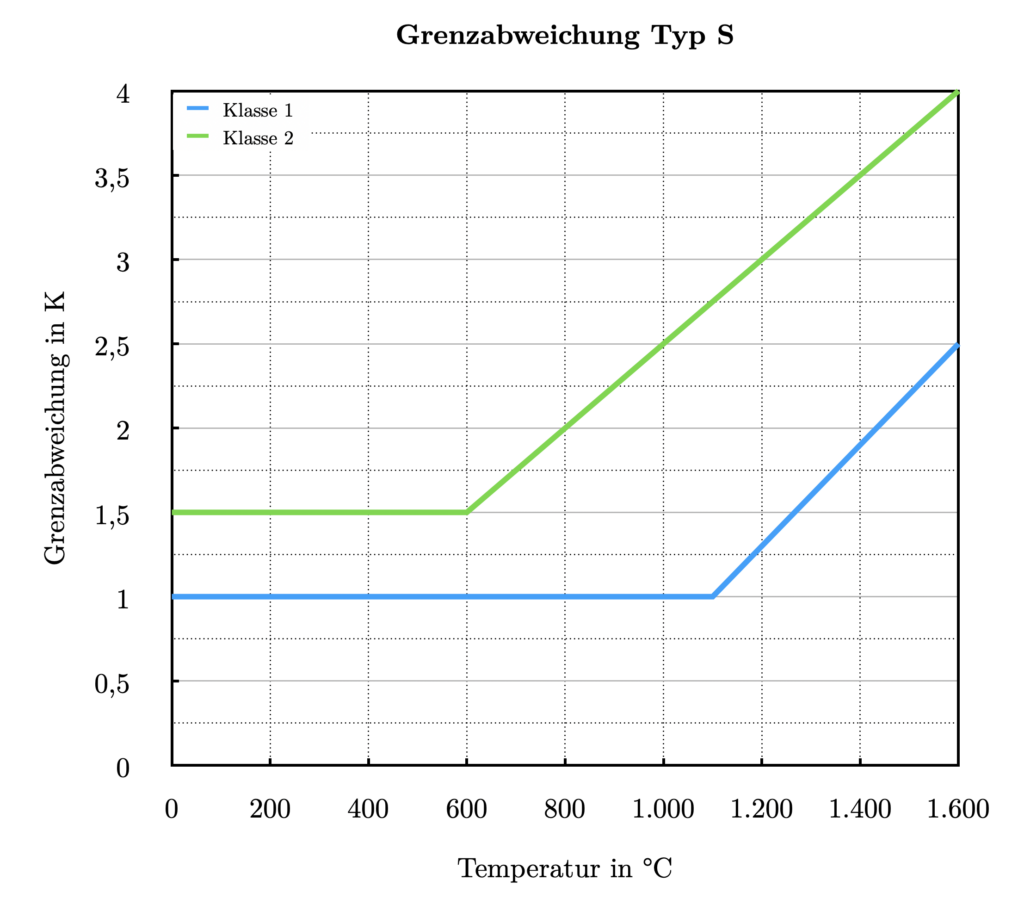

Limit deviations of thermocouples

Limit deviations are the maximum error or inaccuracy that can occur when measuring temperature with a thermocouple.

The limit deviation is specified in the IEC 60584 standard for thermocouples and indicates the maximum allowed error that may occur in the temperature measurement in order to still be considered compliant with the standard. The limit deviation will be given as an absolute temperature value (e.g. ±1°C) and in the higher temperature range as a percentage of the measured temperature.

There are different classes of thermocouples, each with different limiting deviations. Some examples:

- Class 1: These thermocouples have the lowest limiting deviations and are used for precise measurements.

- Class 2: These are slightly less accurate than class 1, but are still used in many applications.

- Class 3: These have the largest limiting deviations and are used in applications where accuracy is less critical.

It is important to note that the actual performance of a thermocouple is also influenced by other factors, such as the quality of the materials used, the construction of the thermocouple and the conditions in which it is used. Therefore, it is critical to specify and use the thermocouple correctly to ensure that measurements are within expected limits.

Limit deviation type K

Limit deviation type N

Limit deviation type R

Limit deviation type S

The K effect of type K thermocouples

Type K thermocouples, made up of NiCr and NiAl thermocouple wires, are widely used in industry and offer many advantages thanks to their ability to be used over an extremely wide temperature range (-270°C to 1372°C) and their high sensitivity at industrially relevant temperatures. However, they are not without faults, especially in a specific temperature range. This is the so-called “K-effect”.

Background

Although type K thermocouples can be used in an extremely wide temperature range, they are only reliable in everyday use below 250°C or above 600°C. This is due to a special phenomenon, called the “K effect”. This is due to a special phenomenon known as the K-effect or type K state.

The K-effect:

The NiCr leg of a type K thermocouple has an ordered alignment in the crystal structure below 400°C. If the element is heated above this point, a transition to a disordered state takes place between 400°C and 600°C. Only above 600°C does the crystal structure become ordered again.

However, cooling this thermocouple too quickly causes problems. At cooling rates of more than about 100°C per hour, the crystal structure does not transform as it should and remains in a disordered form. This can lead to a thermoelectric voltage error of up to 0.8 mV, which corresponds to a difference of about 5°C.

It is interesting to note that this K-effect is reversible. By so-called annealing the thermocouple at temperatures above 700°C and then cooling it more slowly, the grid can be largely restored to its original status.

Relevance for industry:

Because of this K-effect, type K thermocouples are unsuitable for measurements between 250°C and 600°C, where the temperature changes rapidly. In this range they can have very large and non-reproducible errors, often in the order of 2°C to 10°C.

Final thoughts:

While Type K thermocouples are widely used in industry because of their many advantages, such as a wide operating temperature range and their economy, their range of application must be carefully considered. In particular, unreliability in the 250°C to 600°C range due to the K effect can cause significant measurement errors.

It is recommended to consider alternatives such as the type N thermocouple (NiCrSi-NiSi), which is less susceptible to this effect.

Conclusion

Thermocouples are simple but powerful instruments for measuring temperature. They are based on the Seebeck effect and produce a measurable voltage that depends on the temperature. This technology has found wide applications in industry and research and provides a reliable method of measuring temperature, especially at high temperatures.

Source

- Frank Bernhard: Handbuch der Technischen Temperaturmessung, 2. Auflage

- Thomas Klasmeier: Tabellenbuch „Temperatur“, Ausgabe 3